What Is Plumbing Flux (Learn How To Use It Like A Professional!)

If you’ve ever watched a plumber solder a pipe joint, then you’ve seen him use plumbing flux. But what the heck is it and how can you use it in your DUY projects? Let’s find out!

What is Plumbing Flux?

Flux is an acidic paste that is widely used in plumbing applications to link two joints that are soldered together. This is referred to as “sweating” the pipes. Flux, when combined with solder, is an important component of the sweating (or soldering) process.

Attempting to solder without flux will bring unnecessary difficulties to your soldering process. Understanding flux and how to use it can help you connect your copper fittings properly and create a long-lasting water-tight seal.

What is Plumbing Flux Made From?

Flux is a chemical agent (trisodium phosphate) that is used to clean and combine metals. It comes in liquid and paste forms and is created from organic or inorganic ingredients. Which you use depends on the qualities you’re looking for in your project.

What is Flux Melting?

Flux is acidic in nature, and it not only cleans the copper pipe, but it also draws the flame to it. This brings the melted alloy with it and forms a watertight seal. It is critical to have a proper connection during soldering in order to avoid future leaks and water damage.

How to Apply Plumbing Flux

For plumbing purposes, you want to use an acid flux or lead-free tinning flux for soldering copper pipes as these are the two best options. Larger areas of oxidation can be removed with acid flux, resulting in much stronger soldering work.

1. Clean & Prepare Pipes

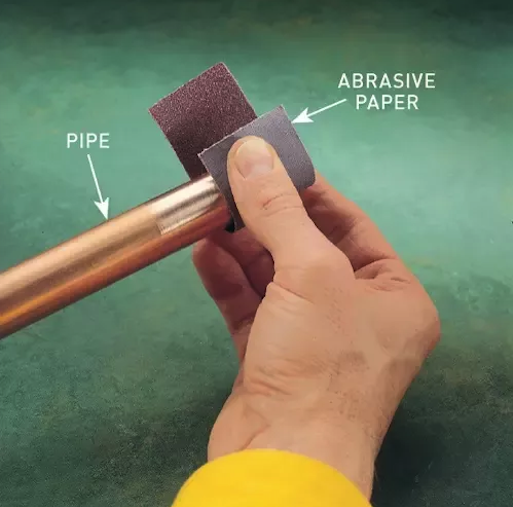

- Make sure the area where you’ll be soldering is clean. Clean any grime or dirt from any sections of your pipes and fittings that need to be soldered with sandpaper, steel wool, or anything abrasive. This will allow your solder to adhere to the pipe more tightly, resulting in a more secure connection.

- You should only have to clean around 1 to 2 inches of piping to make soldering easier. If you’re using a larger pipe fitting, you may need to clean it more thoroughly to ensure that the point of overlap between the pipe and the fitting is ready to solder.

- Clean your pipe fittings with 120-grit sandpaper or grade-1 steel wool. This should be sufficient to remove dirt and grime without causing damage to the pipes.

2. Apply Flux to Pipes

- Apply a thin layer of flux to the ends of your pipes and the insides of your pipe fittings with a little paintbrush.

- Look for any large lumps of flux around the pipe’s edges and be sure to brush them out.

- Acid flux or tinning flux are the two best options in this case.

- It is always a good idea to seek advice from your local hardware store on the appropriate sort of flux to use for the project at hand.

3. Wipe Away Extra Flux

- Hold the two pieces that need to be connected in each hand. Secure the two ends together until they are completely linked.

- With a clean paintbrush, wipe away any flux that may have come off in the process.

- Before you start soldering, you should join a section of a few pipes together.

- Working on one area at a time could be slow, but dealing with a large section all at once could prove to be difficult.

Final Thoughts

That’s all there is to it. You’ve used the flux to clean and connect. You’re now ready to begin soldering. We have some great instructions on how to solder (or sweat) a copper pipe correctly. That article is below in our Related Resources.

Related Resources

- Sweating pipes the right way: step by step

- Soldering safety tips!

- How to find pipes behind walls

- What do you know about pipe fittings?

- 5 main types of plumbing pipes

- Copper vs PEX pipe

- How to use compression fittings on copper pipes

- Push-to-connect fittings (replaces soldering)

Call 1-Tom-Plumber

Don’t hesitate to contact us here or call us at 1-Tom-Plumber (1-866-758-6237) if you need help soldering your plumbing pipes.

1-Tom-Plumber’s certified team of plumbers and drain technicians respond immediately to any emergency plumbing, drain cleaning, or water damage problem. We also handle the excavation of underground water lines and sewer main lines. Our immediate-response team is available every day and night of the year, even on holidays.